Slider Bed

Smooth (Standard) - #304 Stainless Steel. Available in 16 GA – 7 GA.

**Gauge range: 16 (light duty chip handling) - 7 (heavy duty parts and scrap handling)

Textured - #304 Stainless Steel. Available in 16 GA or 12 GA. Provides added strength and eliminates oil-film cohesion of flat stampings.

**Gauge range: 16 (light duty chip handling) - 7 (heavy duty parts and scrap handling)

Impact Overlay - #304 Stainless Steel. Available in 16 GA – 7 GA. Can or cannot be the same as the base slider plate. Paired with either a smooth or textured base slider plate. An impact sheet for the impact area of the conveyor to increase life of base slider plate. Goes on top of the base slider plate and is replaced when needed.

**Gauge range: 16 (light duty chip handling) - 7 (heavy duty parts and scrap handling)

Manganese Steel - Non-ferrous armor plating for the impact area of the conveyor. Welded to the base slider plate, so it is irreplaceable. 3/16” thick.

**Gauge range: 16 (light duty chip handling) - 7 (heavy duty parts and scrap handling)

Motor Control

- Non-reversing manual on/off single phase motor starter with thermal overloads. Up to 1 HP @ 110 V.

- Non-reversing manual push button three phase motor starter with thermal overload relay size “0”. NEMA 12 enclosure. Up to 3 HP @ 230 V, or 5 HP @ 460 V.

- Combination magnetic motor starter. Fused disconnect, size 1, NEMA 12, JIC, non-reversing contactor with overloads, start/stop pushbuttons, pilot light, 110 V control transformer. Available for 208 V, 230 V, 380 V, 460 V, or 575 V, 3-phase.

- Variable speed controls available for all voltages.

Leg Support

Height Adjustable

- Slot Adjustable (+/- 3) – Standard

- Screw Adjustable (+/- 1)

Fixed

Nonadjustable

Casters

Wheels available for easy transportation

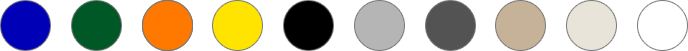

Paint

- Enamel Finish (Standard)

- Custom Finish

- Epoxy

- Polane

- Standard Colors:

- RAL Colors

- Custom Colors

Hopper

Hopper

*Hopper may not be required for your application

Coolant Handling Hopper

- Reverse-Flow Hopper - For the input area, aids in effective removal of most chips and ferrous contaminant from coolant, increasing useful life of liquid and saving wear and tear on pumping equipment. For low coolant volumes.

- Lateral Flow Hopper - Same use as Reverse-Flow Hopper. For high coolant volumes.

*Hopper may not be required for your application

Drive Mounting

- Shaft-Mounted (Standard) - only used for <1 HP motors

- Top-Mounted - for motors >1 HP

- Side-Mounted - for motors >1 HP

Standard mounting positions: H1, H2, H3, H4, V1, V2, V3, & V4

Additional Options

Air Knife

Smoke Covers

Pivot Chutes

Slider Plate Covers

Access Panels